For car enthusiasts, builders, and racers, the quest for extreme horsepower is never-ending. Whether you’re restoring a classic muscle car, building a drag racing beast, or creating a high-performance street machine, crate engines offer a plug-and-play solution to unlock jaw-dropping power. These pre-assembled, factory-tested engines save time, reduce complexity, and deliver reliable performance straight out of the box. In recent years, manufacturers have pushed the boundaries of what’s possible, offering crate engines that exceed 1,000 horsepower—complete with advanced technology and race-ready durability.

In this guide, we’ll explore five of the most powerful crate engines on the market, each capable of delivering over 1,000 horsepower. From drag strip dominators to street-legal monsters, these engines are redefining what’s possible in the world of high-performance builds.

What Are Crate Engines?

Crate engines are fully assembled, ready-to-install powerplants designed for a wide range of applications. They’re ideal for enthusiasts who want to upgrade their vehicle’s performance without the hassle of custom engine building. With options ranging from naturally aspirated V8s to supercharged beasts, crate engines cater to every need, whether it’s drag racing, street performance, or muscle car restoration.

Top 5 Crate Engines Over 1,000 Horsepower

Here are five of the most impressive crate engines that deliver over 1,000 horsepower:

1. Mopar DSR1500-DC: The Drag Strip Dominator

The Mopar DSR1500-DC is a drag racing powerhouse developed in collaboration with Don Schumacher Racing, a legendary name in NHRA competition. This supercharged HEMI V8 is engineered for maximum efficiency and consistency on the drag strip.

- Key Features:

- Supercharged HEMI V8 configuration.

- High-strength materials and reinforced internals.

- Advanced cooling solutions for extreme conditions.

- Precision tuning for seamless power delivery.

- Ideal For: Dedicated drag racing builds where every component is optimized for acceleration.

2. Ford Megazilla 2.0: Power Meets Drivability

The Ford Megazilla 2.0 is an evolution of the popular Godzilla 7.3L V8, designed to deliver over 1,000 horsepower while maintaining Ford’s reputation for durability and reliability.

- Key Features:

- Gen 6 3.0-liter Whipple Supercharger.

- Forged pistons, connecting rods, and steel crank.

- Upgraded valve springs and ported cylinder heads.

- Aluminum heads for improved heat dissipation.

- Ideal For: High-performance street builds and modern muscle car swaps.

3. BluePrint Engines 632 c.i. ProSeries: Naturally Aspirated Beast

The BluePrint Engines 632 c.i. ProSeries proves that you don’t need forced induction to achieve extreme horsepower. This naturally aspirated big-block V8 delivers over 1,000 horsepower with precision engineering and high-rev capability.

- Key Features:

- 632 cubic inches of displacement.

- CNC-machined cylinder heads for optimized airflow.

- Forged internals for durability.

- Available in carbureted or fuel-injected versions.

- Ideal For: Drag racing and competition builds that rely on brute force.

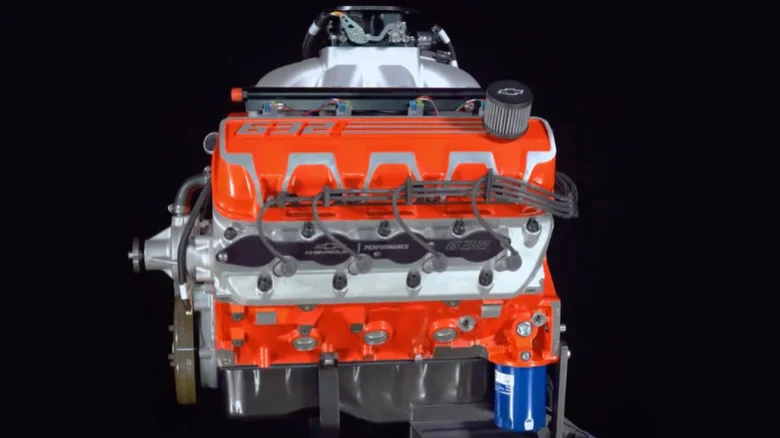

4. Chevrolet Performance ZZ632/1000: The Big-Block Legend

The Chevrolet Performance ZZ632/1000 is a 1,000-horsepower big-block V8 designed for serious racers and street enthusiasts. With race-proven components and advanced technology, it’s a powerhouse that doesn’t compromise on performance.

- Key Features:

- 632 cubic-inch displacement.

- Identical intake and exhaust ports for balanced airflow.

- Electronic fuel injection (EFI) and advanced ignition system.

- Impressive torque output for heavy-hitting builds.

- Ideal For: Muscle car restorations and high-performance street builds.

5. Mopar Hellephant: The Supercharged Icon

The Mopar Hellephant is one of the most legendary crate engines on the market, offering over 1,000 horsepower with its supercharged 426 cubic-inch HEMI design. It’s a collector’s item and a performance icon.

- Key Features:

- 3.0L supercharger for extreme power.

- Forged pistons and reinforced bottom end.

- Available in aluminum or cast iron block variants.

- Compatible with premium fuel or E85.

- Ideal For: Modern muscle car builds, restomods, and collector vehicles.

Why Choose a Crate Engine?

Crate engines offer several advantages for car enthusiasts and builders:

- Time-Saving: Pre-assembled and ready to install, crate engines eliminate the need for custom engine building.

- Reliability: Factory-tested and engineered for performance, these engines are built to last.

- Performance: With options exceeding 1,000 horsepower, crate engines deliver track-ready power without extensive modifications.

- Warranty: Many crate engines come with a manufacturer’s warranty, providing peace of mind.

Choosing the Right Crate Engine for Your Build

When selecting a crate engine, consider the following factors:

- Application: Are you building a drag racer, street machine, or restomod? Choose an engine designed for your specific needs.

- Budget: Crate engines range from 20,000to20,000to40,000+, so set a budget and stick to it.

- Compatibility: Ensure the engine fits your vehicle’s chassis and drivetrain.

- Fuel Type: Some engines are optimized for premium fuel or E85, so choose one that aligns with your preferences.

Unleash the Power

Crate engines have revolutionized the world of high-performance builds, offering enthusiasts a hassle-free way to unlock extreme horsepower. Whether you’re drawn to the drag-focused Mopar DSR1500-DC, the street-friendly Ford Megazilla 2.0, or the legendary Mopar Hellephant, there’s a crate engine to suit every build and budget.

As technology continues to advance, the possibilities for crate engines are endless. With options exceeding 1,000 horsepower, these powerhouses are redefining what’s possible on the track and the street. So, what are you waiting for? It’s time to unleash the power and take your build to the next level.